Magnetic Particle Inspections (MT)

A process utilising flux leakage through direct or alternating currents. Good for detection of flaws open to the surface. Used on ferromagnetic materials only.

Dye Penetrant Inspections (PT)

This process, by means of capillary action allows the penetrant to pentrate the flaw. The process is then reversed with blotting; in doing so, the flaw is revealed. Best used on smooth surfaces.

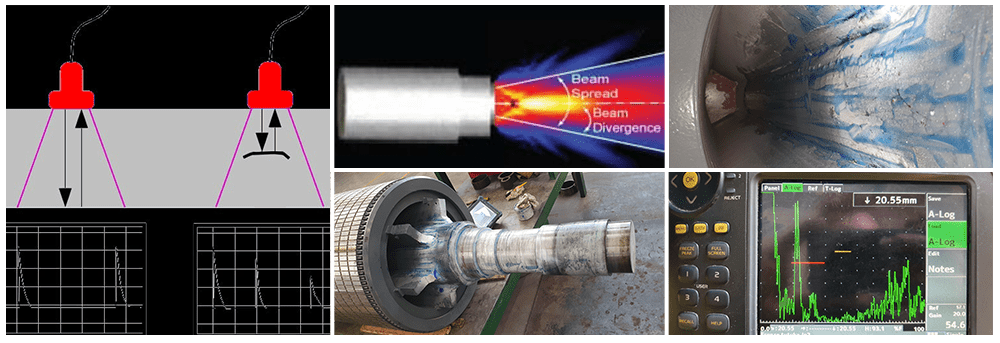

Ultrasonic Inspections (UT)

Sound is directed into the material; the returning energy is analysed to establish the presence or absence of subsurface flaws.

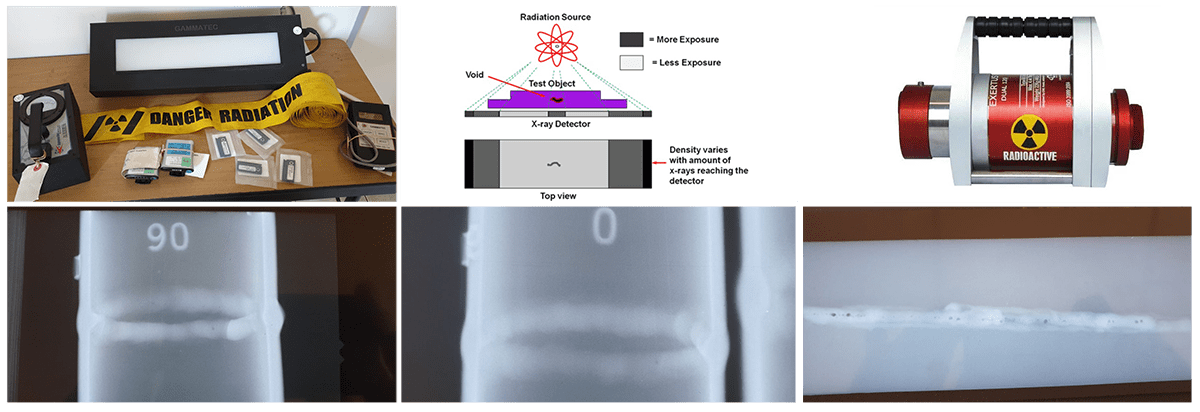

Radiographic Inspections (RT)

X-rays or Gamma rays are used to detect subsurface flaws. The image of the specimen is transposed onto film. Used on most materials.

Phased Array Inspections (PA)

With phased array, the probe is sequentially pulsed to produce an array of angles. Good for both detection and sizing.

Positive Material Identification (PMI)

A method whereby the individual material composition is determined in order to classify/identify types of metallic materials.

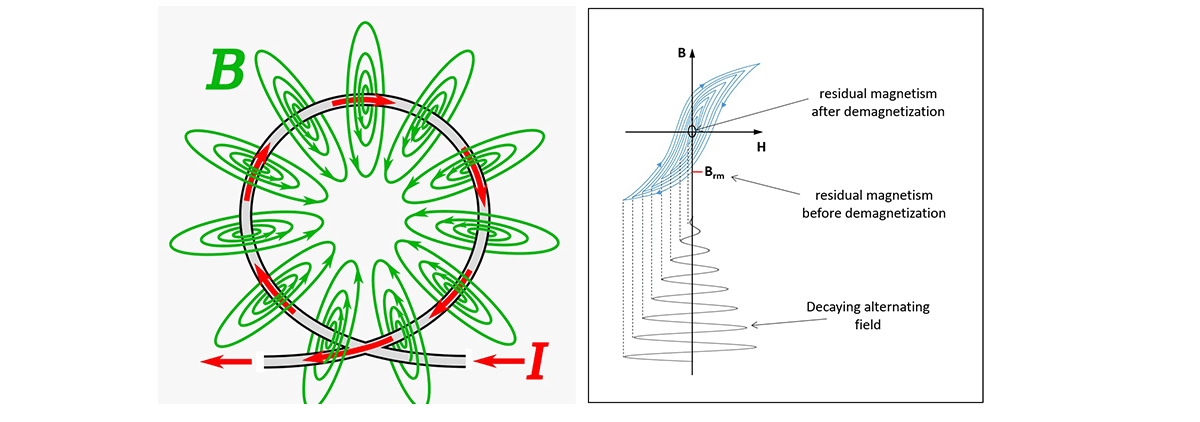

Demagnetising

A process conducted in order to remove / reduce residual magnetism left in ferromagnetic materials following their subjection to high density magnetic fields.

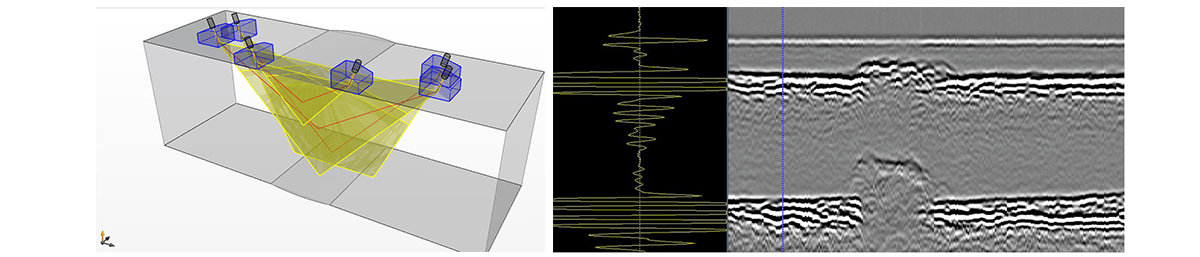

Time of Flight Detection (TOFD)

Fixed scanning pitch and catch methodology utilising the diffracted signal. Good for flaw detection and best for flaw sizing.

Potential Drop (Crack Depth Measurement)

By measuring the potential drop across two points, the flaw depth is determined.

Eddy Current Inspections (ET)

Used to detect surface and subsurface flaws in conductive materials. Can also be used to measure coating thickness.

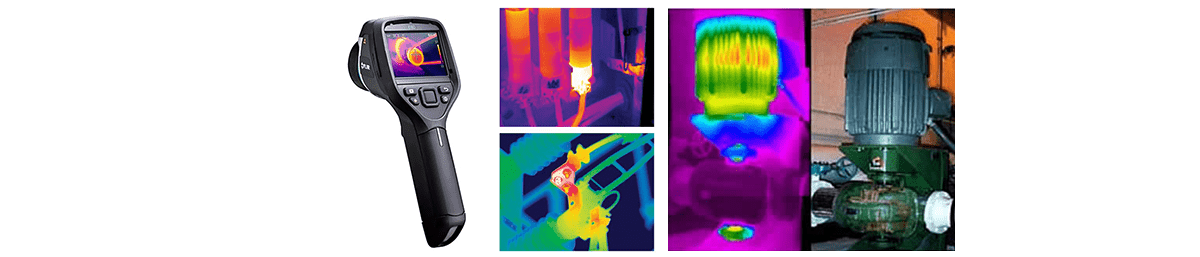

Thermographic Inspections (Thermography)

Method to detect heat variation from a distance.

Welding Inspections

A process of inspecting welding, ensuring compliance to relevant codes. This function often includes validation/ compilation of Procedures Qualification Records (PQR) Welders Qualification Records (WQR) and Welding Procedure Specification.

NDT Level III Services

As per procedural requirements, the Level III’s function will include the following:

- Ensure inspection techniques / procedures are compliant,

- Subcontractors and personnel meet the code requirements,

- Authorisation of personnel,

- Perform internal /external surveillance audits / assessments,

- Oversee training,

- Validate technique selections,

- Evaluation of NDE data.

Replica Inspections

A process that enables the surface of the specimen to be replicated, thereafter viewed under a microscope to evaluate the microstructure.

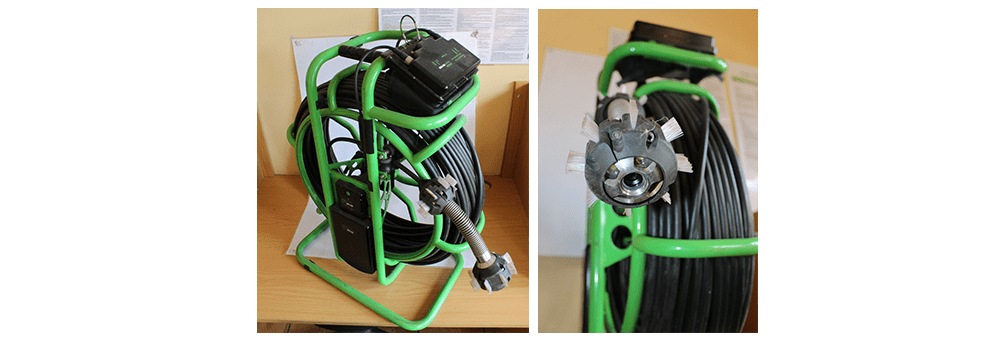

CCTV PIPING

CCTV Inspection is a method where by a camera is inserted into a pipeline or an inaccessible area of a test piece or component in order to inspect for flaws, corrosion or blockages to name a few.

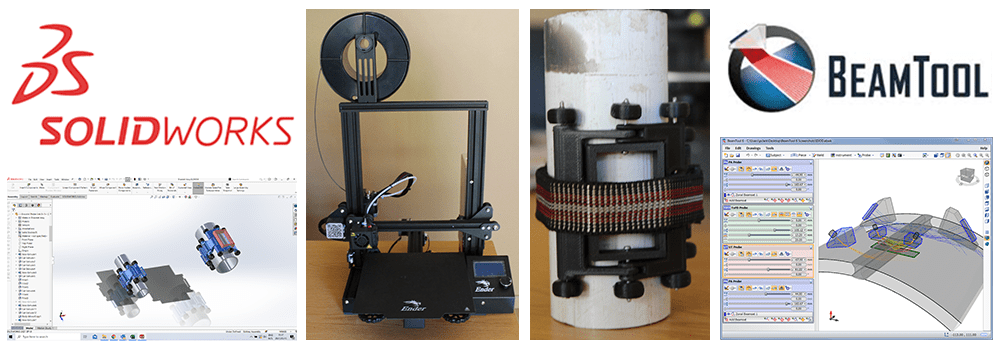

RESEARCH AND DEVELOPMENT WORK

Spectra Ndt utilizes a variety of tools at our disposal in the development of custom equipment and inspection techniques (Beam Tool, SolidWorks and machining facilities to name a few)